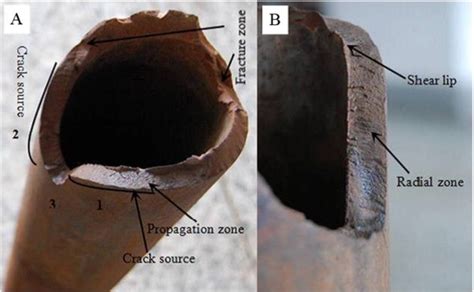

difference between fatigue test and creep test|fatigue vs creep : dealer fatigue is stress/time dependent and the effect of a cyclical stress system is to cause nucleation and propagation of cracks within the material. Final failure is by fast fracture when one or more .

Junte-se a nova Plataforma Fortune777! Comece agora a desfrutar dos melhores games. Convide amigos e ganhe uma recompensa por cada convite! Seja um Vencedor na .

{plog:ftitle_list}

You’ll get a 100% deposit bonus worth up to $1,000 and a $25 no deposit bonus after signing up with our promo code No code needed at BetMGM Casino in MI, NJ, and PA. As an example, a deposit of .

Creep results in deformation, while fatigue leads to crack propagation. Both ultimately lead to the failure of the material, by compromising its structural integrity, resulting in an eventual split or rupture. How to test for metal creep or fatigue in metals.

In materials science, fatigue is the progressive, localised, and permanent structural damage that occurs when a material is subjected to cyclic or fluctuating strains at nominal stresses that . In low temperatures, creep depends only on stress. In high temperatures, creep depends on stress, temperature, and time. Fatigue failure occurs due to constant cyclical . Fatigue testing is most relevant for materials experiencing varying loads, such as those in bridges and automobiles. In contrast, creep testing is crucial for materials exposed to .What is the difference between creep test and fatigue test? Creep testing measures how a material deforms under constant load over time, while fatigue testing examines how it responds to repeated cyclic loading.

fatigue is stress/time dependent and the effect of a cyclical stress system is to cause nucleation and propagation of cracks within the material. Final failure is by fast fracture when one or more .1. Strain-controlled tests with hold periods at constant stress or strain. 2. Creep tests under cyclic stress or strain. 3. Interspersed creep and fatigue tests.

what is creep testing

The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) or creep-fatigue crack growth (CFCG) tests with .Conceptually a creep test is rather simple: Apply a force to a test specimen and measure its dimensional change over time with exposure to a relatively high temperature.tion into the relationship between fatigue and creep. The fatigue tests studied in detail were the repeated-load indirect tensile test, the two-point flexure test used by Monismith et al, the rotating cantilever test used by Pell et al, and the axial load test performed by . The large differences between test results obtained

Creep tests were carried out under the guidelines provided in . Tests (constant or variable loads) were always started at about 10 min after stabilizing the sample temperature to 600 °C. The temperature of a sample during the fatigue tests (program f) and creep tests (program c) was maintained automatically by the heating chamber control system.Creep-fatigue interaction behavior of ferritic steels and austenitic stainless-steels — covers properties, test methods and the latest models for applying the test data to components. Creep-fatigue interactions in nickel-base superalloys being considered for use or already in use in advanced nuclear plants and in gas turbines — discusses .Creep-Fatigue interaction is widely studied for many different applications relating to high temperature materials and in particular a large quantity of literature can be found for power plant component materials. In the last years a great effort has been spent to define a standardized procedure for the creep-fatigue testing and assessment (e.g., [1, 2]).Coffin (1973) carried out numerous studies in various wrought and cast superalloys, and thoroughly investigated the influence of frequency in a Fe–Ni-based superalloy in air and in high vacuum (1.3 μPa). Fatigue life strongly decreases with decreasing test frequency in air, when plotted as a function of plastic strain range. The influence of frequency is almost negligible .

2.1 Creep-fatigue mechanisms . 2.1.1 General overview . Creep-fatigue is the initiation and subsequent growth of flaws under cyclic load interspersed with hold periods at constant, or slowly varying, load. For the purposes of engineering design and assessment creep-fatigue interaction expresses the experimental that a strain- observation

Creep-fatigue tests are conducted at 760°C with strain dwell either at tensile peak or compressive peak or at both tensile and compressive peak positions for different dwell times of 100 and .The creep and fatigue test results at different temperatures showed that the proposed creep rupture time model and the fatigue-creep damage model considering the damage mechanisms can successfully predict the creep and fatigue lives of unidirectional laminates at high temperature, and the prediction results are in good agreement with the .Bluehill Universal Brochure. Bluehill Universal Software is built from the ground-up for touch interaction and an intuitive user experience. Discover simpler and smarter testing with features such as pre-loaded test methods, QuickTest in seconds, enhanced data exporting: and Instron Connect – a new feature that provides a direct communication link to Service.In materials science, creep (sometimes called cold flow) is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses.It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally .

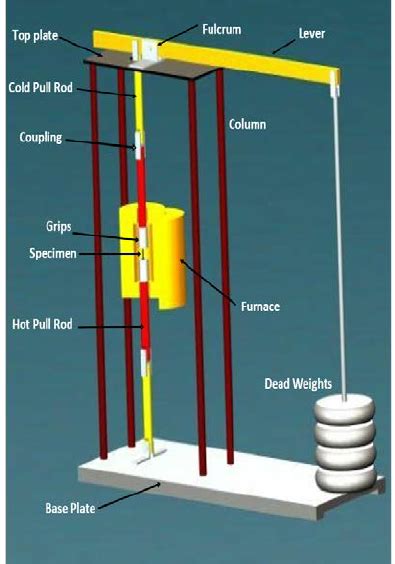

Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. A creep test is one in which the specimen is heated for an extended period and supplied with a constant tensile force or tensile stress. There is a clear delineation between [.]This ASTM E2760-19e1 test is intended as a guide for creep-fatigue testing performed on materials for research and development, mechanical design, process and quality control, product performance, and failure analysis. The fatigue crack will begin on the point of the notch and extend through the sample. The result from this test method can be .

Creep is the gradual deformation of a material under a constant load or stress over a long period of time. It is an important phenomenon to consider in mechanical testing, especially for high .Fatigue and Creep loading conditions00:00 Introduction00:28 What is creep01:06 Examples of Creep failure01:23 Creep with respect to strain and time01:57 What. You can get away with simpler load-control testing if your global applied stresses are below the yield strength - this would often be the case for high-cycle fatigue testing, but for low-cycle . There was no significant difference between virgin, regrind and laminate HDPE in terms of tensile properties. . The results for creep-fatigue interaction tests for virgin and laminated HDPE at 23 °C and 82 °C are shown in Fig. 16. . Another observation from creep-fatigue interaction test results in Fig. 16 is that linear damage rule is .

This work focused on the interaction of creep and fatigue and cyclic strain analysis in high-chromium ferritic P92 steel based on load-controlled creep-fatigue (CF) tests and conventional creep test at 873 K. Mechanical testing shows that the cyclic load inhibits the propagation of creep damage in the P92 steel and CF interaction becomes more severe with .

The creep rupture test (stress rupture test) is used to measure the strength of materials that are subjected to constant stress at elevated temperatures. . Note that with creep rupture tests there are no permanent strengths as with fatigue tests, i.e. the specimen will sooner or later always suffer plastic deformation or breakage, no matter . Dynamic creep and fatigue testing are essential in understanding the behavior of materials under repeated or cyclic loading, which is common in many engineering applications. This information is crucial in designing and selecting materials for structures and components that need to withstand high stress or strain over an extended period of time.

2.1. Mechanism of Creep-Fatigue Cracking. The development of creep-fatigue damage in most power plant steels depends on temperature, strain range, strain rate, hold time, and the creep strength and ductility of the material [1,2,3,4].In the absence of a significant hold time (and/or at relatively high strain rates), crack initiation and growth is fatigue dominated, . These two processes compete with each other and show a difference in evolution with cycles. Mean strain rates for different stress and mixed control tests have also been determined; by comparing the creep strain accumulation rate and plastic strain rate, the competition of creep and fatigue processes has also been demonstrated in this article.

Creep or stress rupture test data are normally plotted as stress versus rupture time (t R) on a log-log plot as shown in Fig. 7-36.Each data point represents one test at a specific temperature and stress level. Given sufficient testing at different temperatures, a complete profile of the material response is obtained.

It is very difficult to isolate the properties from creep and fatigue separately. Cabet et al. [37] conducted creep-fatigue and continuous cycle fatigue test of Alloy 617 at 950 °C, and observed tansgranular cracking and intergranular cracking for pure fatigue and creep-fatigue test, respectively. Without the of creep cavitation, they suggested that environment may exert .

Rotating bending test and reverse bend test. A special type of fatigue test is the rotating bending test, where a round specimen is subjected to an alternating bending stress in order to test bending fatigue strength. Due to the constant bending moment and rotation, the tensile and compressive stresses produced in the material change permanently.introduced. The similarity in creep-fatigue lives suggests that a dwell time imposed at peak tensile strain is more damaging, with regards to cyclic life, at 550 °C than at 650 °C. With respect to the objectives of this research, the difference in creep-fatigue behavior and performance between the two test temperatures indicates important Generally, the creep-fatigue behavior of materials is obtained by tensile/compression tests. In the present study, we explore the possibility of investigating the creep-fatigue behavior of aluminum alloy 2A12 at 200 °C by using indentation creep-fatigue test with a flat cylindrical indenter.The experimental results show that the evolution of indentation .A contact-type HT extensometer, which is also water-cooled, is used to record deformation. The test programs for creep-fatigue test, such as creep crack growth (CCG), low-cycle fatigue (LCF), creep-fatigue (CF), fatigue crack growth rates (FCGR) and creep-fatigue crack growth (CFGR) are included in testXpert R. For creep tensile tests in air up .

hardness vs creep vs fatigue

webLetras de Teu Amigo Cuidou. Eu lembro que quando me deixou. Eu bebi por você. O coração tava sofrendo. Não parava de doer. Eu me humilhei demais. Correndo atrás de você. Porque seu beijo vale a pena. Quem não vale é você.

difference between fatigue test and creep test|fatigue vs creep